Quality

As a key supplier to the Ford Alloy Wheel Plant in the 1990s, Glucina remelted and refined swarf from machined alloy wheels and cast it into certified ingot that was remelted by Ford to make more wheels. We were well versed in the Ford quality philosophies of customer focus and continuous improvement, becoming their first Q101 supplier, followed by Q1 status.

|

Managing Director Tony Trubuhovich receiving Quality Award fron Ford Alloy Wheel plant manager Ken Butler. |

The company also achieved ISO 9002 quality status and had an internationally registered laboratory with an optical emission spectrometer for chemical testing.

Sadly the Ford Alloy Wheel plant no longer exists and although Glucina is a smaller operation employing fewer people today, we still adhere to the earlier quality philosophies.

Detailed analysis of the manufacturing process has been carried out to identify the critical steps in the process, leading to written procedures for all alloy production. Statistical process control continues to be a powerful tool and together with customer feedback allows for continuous improvement.

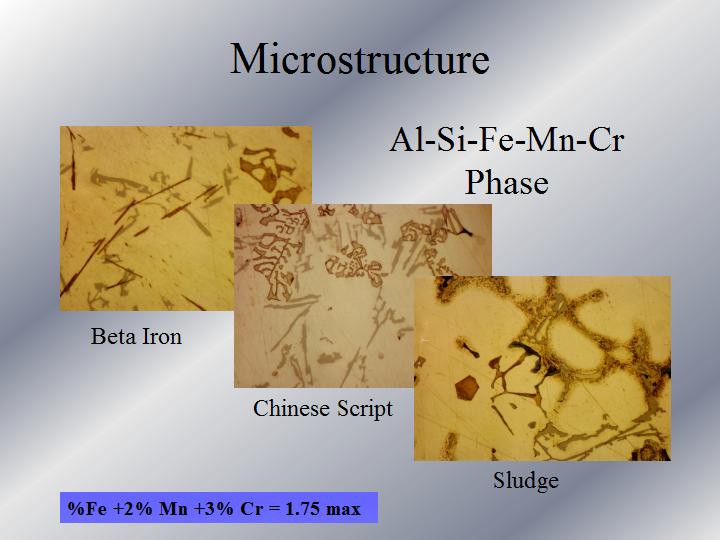

Although Glucina has an optical emission spectrometer capable of analysing up to 26 elements in each alloy base very accurately, loyal customers have learned over the years, there is far more to making quality ingot than simply getting the chemical composition correct. Glucina has carried out extensive research and development to perfect its manufacturing processes and can confidently boast that it does consistently produce the highest quality alloys.

- Expert knowledge

- In-house metallurgist's advice

- Commitment to prompt delivery

- Efficient, professional service

|

Analysis of alloys using spectrometer. |

|

Preparing metallographic specimens. |

|

Microstructures. |