Environment

Environmental Policy

Glucina directors and owners have always put care for the environment at the forefront of their strategic planning and our Environmental Management System is based on the principles of ISO 14001.

Aluminium is considered one of the "greenest" of metals being almost 100% recyclable, i.e. it can be repeatedly recycled, remelted and refined without any loss of quality.

We are proud of the fact that we are capable of recycling aluminium and producing a high quality product for sale in New Zealand and for export. We will continue to highlight the value of recycling technology as environmentally friendly and the important role that an innovative manufacturer and exporter plays in building a strong New Zealand economy.

By using this sustainable process, we are preserving raw materials such as bauxite, from which aluminium is extracted through the "primary" smelting process. In addition Glucina's process of remelting aluminium uses up to 95% less energy and creates up to 95% less greenhouse gas than primary aluminium production. It also reduces landfill waste.

Community

From the time the Resource Management Act was made law in 1991, Glucina embraced the principles of minimising the impact of emissions from its process to air, water and land. Glucina works very closely with the environmental protection agency, Auckland City and complies with strict guidelines as specified in the conditions of its Air Discharge Permit.

Emissions control

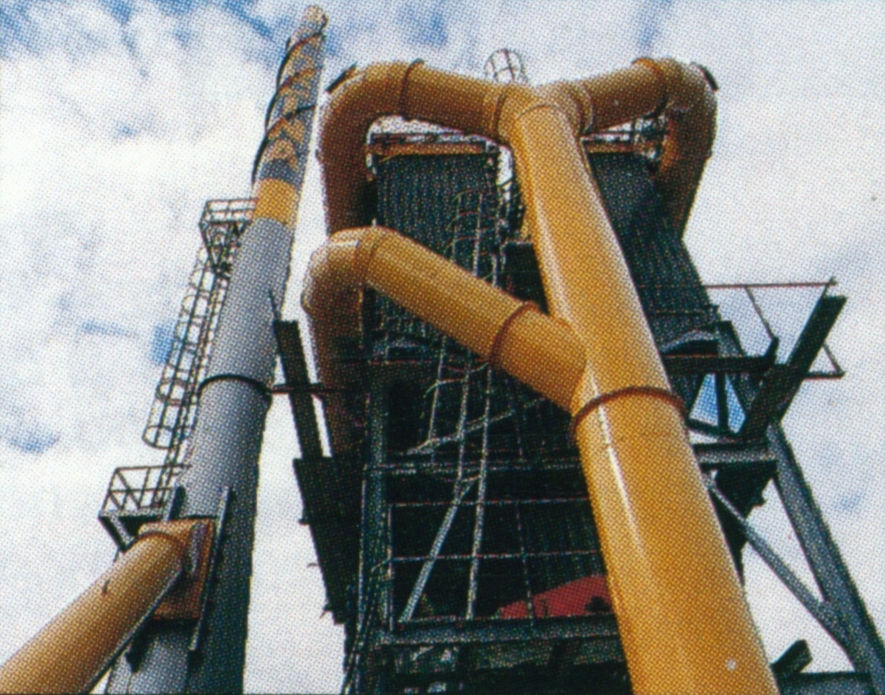

Glucina has invested in a computer controlled fume abatement and monitoring system. All particulate emissions generated from melting furnaces are extracted and passed through a large baghouse filtration unit. (in simple terms the baghouse is like a very large vacuum cleaner, with a total surface area of over 1400 square metres of lime dosed polyester filter material). The system is over designed allowing for future growth and currently ensures emissions are well below the maximum allowed limit.

TARDIS Dross Press

A recent installation of a TARDIS dross press will allow Glucina to treat the aluminium dross (i.e. a byproduct of Glucina's melt process containing aluminium oxide and aluminium that is skimmed off the surface of a melt) to ensure even greater efficiency of aluminium recyclability.

|

Glucina's emissions control baghouse filtration unit. |

|

Glucina meets strict environmental conditions. |